Porcelain tiles are a popular choice for flooring due to their durability, low water absorption, and elegant appearance. Here is an overview of how porcelain tiles are made:

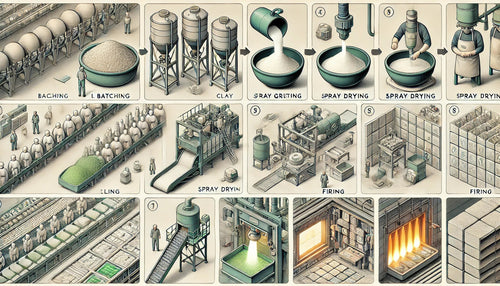

Phase 1: Batching

The process begins with batching, where raw materials like clay, quartz, and feldspar are mixed in precise proportions to achieve the desired tile properties.

Phase 2: Mixing and Grinding

The raw materials are then blended and ground in a ball mill with water, producing a slurry known as slip.

Phase 3: Spray Drying

The slip is spray dried to remove excess moisture, resulting in a fine powder.

Phase 4: Forming

The dried powder is pressed into molds under high pressure to form green tiles.

Phase 5: Drying

The green tiles are dried to eliminate residual moisture.

Phase 6: Glazing and Printing

Tiles are glazed and printed with designs to enhance their appearance and provide a protective layer.

Phase 7: Firing

The tiles are fired at high temperatures (around 1200°C) in a kiln, solidifying the tiles and setting the glaze.

Phase 8: Polishing

Finally, the tiles are polished to achieve a smooth, shiny surface. The edges can be rectified to ensure uniformity and ease of installation.

By following these meticulous steps, manufacturers produce high-quality porcelain tiles that are both beautiful and durable, suitable for various applications in residential and commercial spaces.